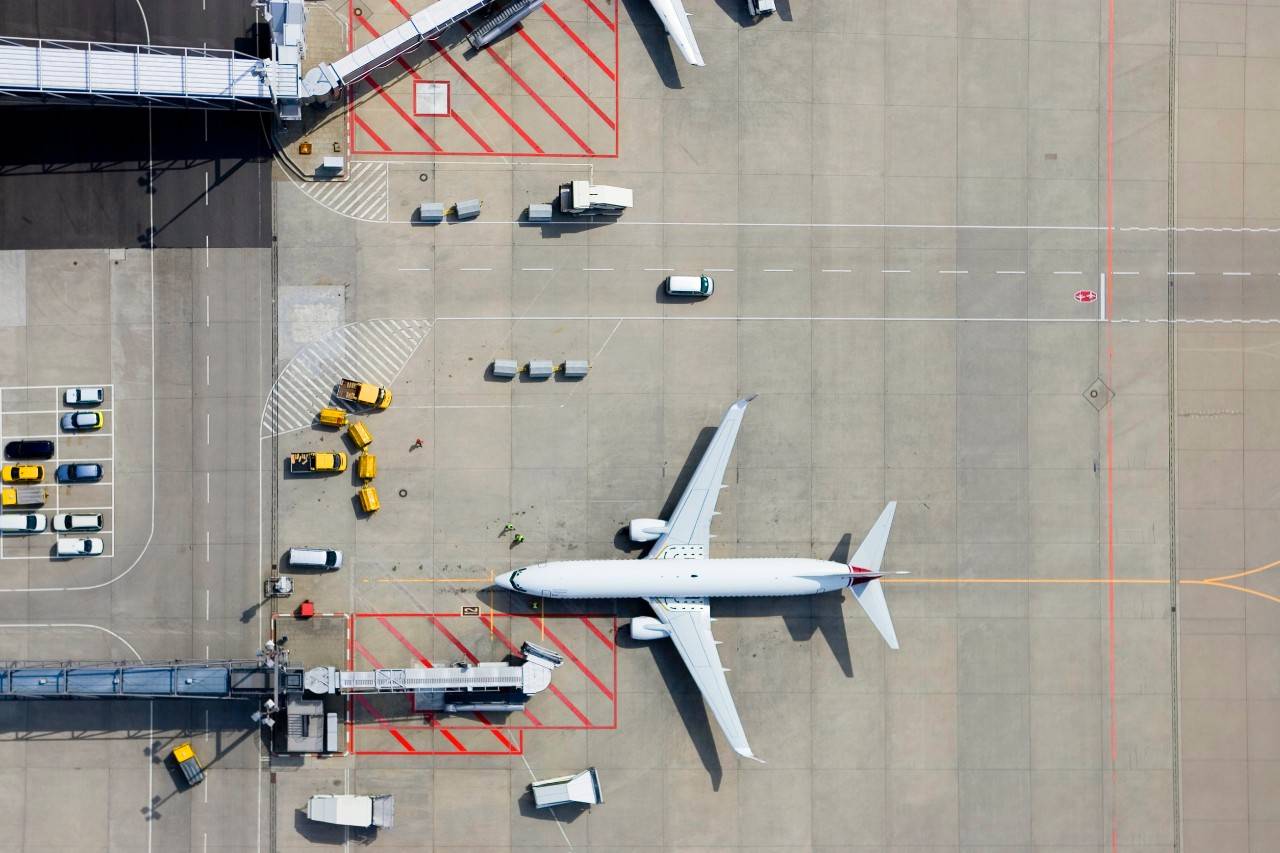

Rising coronavirus levels threaten sector recovery

New figures for July 2020 show that aerospace manufacturing has finally returned to growth.

ADS, the trade organisation for the UK Aerospace, Defence, Security and Space sectors, has reported a 13.6% increase in aircraft production activity in the UK in July compared to June, following four consecutive months of decline due to the coronavirus pandemic. However, aerospace production remains 23.6% lower than the pre-crisis levels of February 2020.

Depressed demand for air travel sees many airlines still running less than half of their normal flight schedules, while also postponing or cancelling orders and deliveries of new aircraft. As coronavirus cases increase in the UK and around the world, the recovery in aviation could be delayed even further. This is putting increased pressure on supply-chain businesses to ‘right-size’, consolidate their capacity, increase productivity, and diversify in order to survive and remain competitive.

Rolls-Royce has embarked on a restructuring programme which would involve closing 5 out of 11 sites while centralising its operations. Redundancies and downsizing continue across the firm’s whole supply chain, with a quarter of aerospace jobs expected to be lost in the Midlands region.

A direct Italian Government grant of almost €200 million to Alitalia has been approved by the European Commission to compensate the airline for damage caused by the coronavirus pandemic. Similar financial assistance in other countries such as France and Germany will make it more difficult for the UK-based airlines to compete unless the British Government provides further support. ADS is calling for modifications to the UK’s current 14-day quarantine policy that can support a recovery in aviation and aerospace, while protecting public health. This would involve the use of travel corridors and increased use of technology together with passenger testing.

Defence

The UK integrated defence and security review is expected in the next few weeks. It will cover all aspects of international and national security policy, including defence, diplomacy, development, and national resilience. Defence secretary, Ben Wallace, has hinted that the armed forces would use drones and other forms of autonomous weaponry rather than large troop deployments to fight future wars. This is a development that’s likely to boost the aerospace and marine defence sectors. However, if a rebalancing of funds is announced, certain areas such as land vehicles and conventional weapons may see budget reductions.

Advanced manufacturing

The Government has announced £147m in funding for the Manufacturing Made Smarter Challenge. This scheme aims to boost UK manufacturing productivity by 30% by helping the industry to adopt digital technologies such as digital twins, additive manufacturing, artificial intelligence, robotics, and automation.

The investment will be industry-matched, providing almost £300m in total. The first £50m tranche will be allocated to 14 cutting-edge manufacturing projects involving around 30 small or medium businesses, 29 larger enterprises and nine universities, with the rest of the funds due over the next five years. Further details and how to apply can be found here

Rail sector

To encourage increased travel, passenger operators in the rail sector increased their services from 7 September to closer pre-pandemic levels. However, passenger numbers are likely to remain reduced for a while yet, especially given the rising level of coronavirus cases and new government restrictions.

High Speed 2 (HS2) main works construction officially began on 4 September for the 225 km Phase 1 of the project. This is set to create around 22,000 new jobs while helping to boost economic growth. The Department for Transport and HS2 Ltd now estimate the cost of Phase 1 at between £35bn and £45bn. Passenger services between London and Birmingham are expected to begin between 2029 and 2033, with the full Phase 1 service from London Euston to follow between 2031 and 2036.

Network Rail has published its interim Traction Decarbonisation Network Strategy, setting out recommendations for decarbonising the UK’s rail network. The strategy recommends electrification of 11,700 track-km, battery operation on 400 km and hydrogen on 900 km. Between 3,600 and 3,800 electric and 150 to 200 battery and hydrogen trains would be required, as well as around 650 to 700 new freight locomotives – providing an excellent opportunity for manufacturers.

Rail Forum Midlands has launched an initiative aimed at SMEs in the rail supply chain as they look to remove weight from passenger rail vehicles. The initiative is open to businesses which would like to collaborate with other smaller firms as well as original equipment manufacturers (OEMs). The challenge is supported by Bombardier, Hitachi, Porterbrook and Siemens with other OEMs/asset managers invited to join.

Manufacturing sector news

UK Manufacturing Facts 2020-21 has now been published as a joint undertaking between Make UK and Santander – access the report here. It shows that the UK’s total global exports stand at £367bn, with the top export markets, in order of size, the United States, Germany, France, Ireland and China.

The report shows that the UK has retained its position as the world’s ninth largest manufacturer with output of £191bn in 2019, up 7% since 2014. Average salaries in the sector are 13% higher than in the rest of the economy, at almost £35,000 a year.

Transport manufacturers are not only the biggest exporters, with the 22% share of the market, but also the biggest spenders on research and development. A fact that highlights the critical importance of the automotive and aerospace sectors to the long-term high value growth of the economy.

You can view more of the report’s information during an online interview with Stephen Phipson, CEO of Make UK, here

Make UK has also recently published its Manufacturing Outlook Q3 2020, in association with BDO, the accountancy and business advisory firm. The survey shows that while the sector has recovered to some extent since the spring lockdown, there look to be challenging times ahead. Output and orders remain way below historic averages, while investment has been cut and just a fifth of firms are operating at full capacity.

Overall, the manufacturing industry is set to shrink by over 10% this year – and Make UK has warned that Brexit-related uncertainty, and the possibility of a no-deal end to the current transition period, are likely to keep investment levels low. However, more companies are feeling positive about the short-term than was the case at the end of the second quarter.

To discuss how Santander can help your business please contact: ccbsectorinsights@santander.co.uk