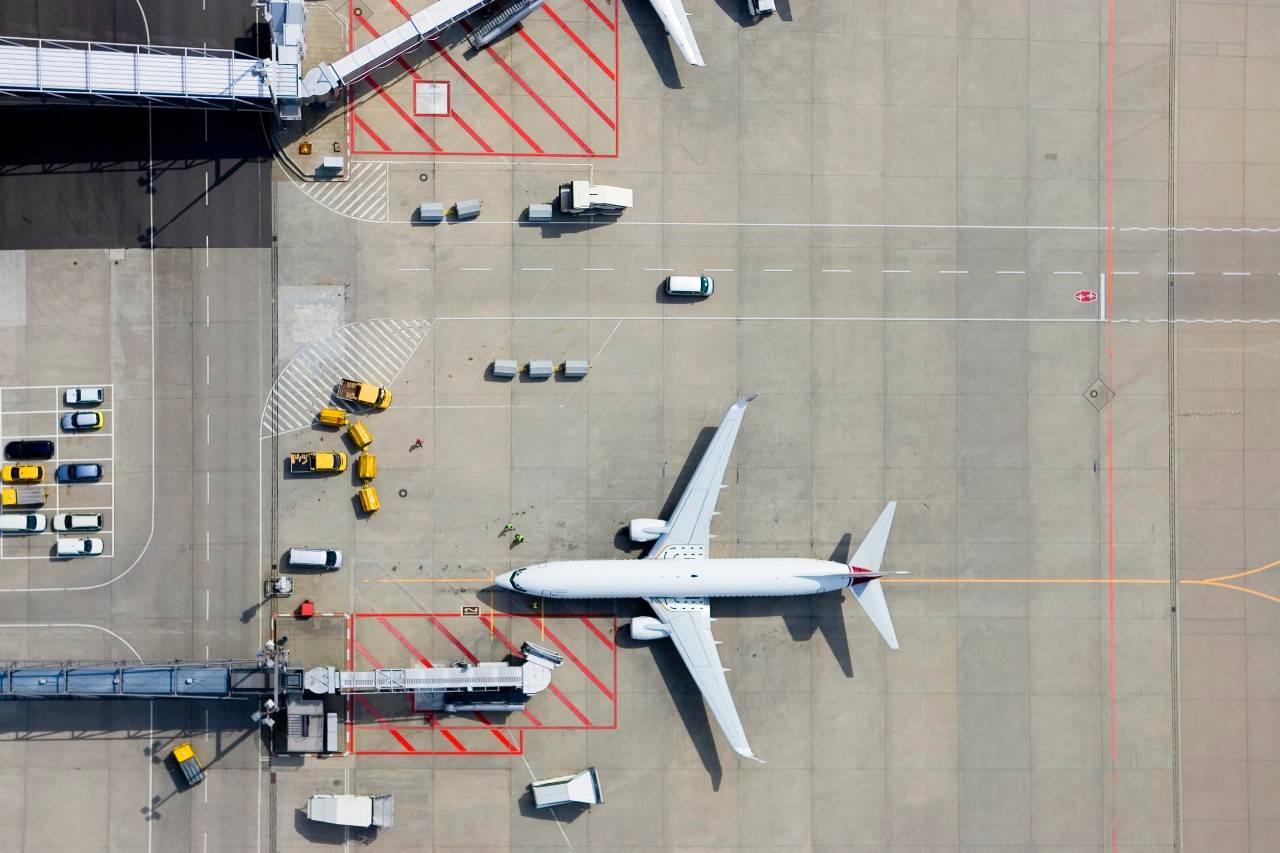

Aerospace looks to the future despite depressed demand

While there have been some tentative signs of improvement, the aerospace sector remains depressed.

Third quarter data from ADS, who represent UK businesses operating in the aerospace, defence, security and space sectors, shows virtually no new commercial aircraft orders and very few deliveries.

New orders in the third quarter were worth just 8.6% of the total achieved in the same period last year. Deliveries remain far below normal levels and are unusually skewed towards single-aisle craft, which are smaller planes. This will impact suppliers in different ways. Rolls-Royce, for example, mainly supplies bigger engines for larger planes, so it and its supply chain will suffer more of an impact.

One surprise is that the overall order backlog has hardly changed. The third quarter saw a decrease of just 1.8% on the same period of last year, due to more deliveries than orders coming in. The global backlog for 13,444 aircraft still represents many years of work and is worth up to £200bn to the UK economy assuming orders are fulfilled.

The impacts of coronavirus are ongoing, with travel restrictions curbing demand for air travel and therefore reducing airlines’ need for aircraft and other services. Recovery is likely to be gradual and the aerospace sector will need ongoing support. Calls for government assistance will therefore increase. This will be important if UK supply chains are to survive and then bounce back.

Positive news ahead

There’s some positive news though. Spirit AeroSystem’s acquisition of Bombardier’s Belfast facility completed on 30 October. This secures the future of an important site, which employs 3,600 people. Bombardier Belfast also has a European supply chain of around 900 approved suppliers, including more than 800 based in the UK and Ireland that receive work worth around £200m a year.

Elsewhere, Rolls-Royce has taken an important step towards financial security, with investors backing a £2bn cash call. The support also enables Rolls-Royce to unlock £3bn of additional debt. The company says that this £5bn takes ‘any liquidity questions off the table through this crisis’, and should help them and their supply chain, of 2,300 companies, get through the disruption of coronavirus.

Boeing is also feeling more upbeat, with the expectation that its grounded 737 Max plane will be re-certificated and able to return to service, and therefore production. However, the company plans to deepen cuts to 19% of its workforce. Boeing’s rival, Airbus, says it’s not planning further job cuts after announcing increased production rates and better-than-expected third quarter results that included a pledge to return to at least breakeven cash flow in the fourth quarter.

In space, the US’s Lockheed Martin is to transfer its satellite launch operations to Shetland in Scotland following government approval. This will help establish the commercial launch market as part of the UK’s space flight programme, LaunchUK. The UK’s space sector is world class, generating £14.8bn of annual revenues. It has ambitious targets to create a £40bn industry by securing 10% of the global space market by 2030.

The rise of the robots

While the UK has historically been slow to adopt robotization, it currently sits in 22nd place in a global ranking of adoption, the challenges posed by labour shortages and the need to improve productivity are forcing more companies to look at automation.

One initiative that could help is Universal Robots’ new leasing programme for ‘cobots’, collaborative type robots that can work safely alongside human operators, which could reduce the upfront cost of automation. Removing the need for substantial upfront investment will enable more companies to try out new robots. Cobots are cheaper than large industrial robots and have a relatively short payback period of typically around a year, which makes them attractive propositions.

One sector where there are real opportunities for automation is the food manufacturing industry. One recent end-of-line automation project at apple producer and packaging business, Adrian Scripps, reportedly tripled productivity per head at the company. We’re working with the Food & Drink Federation, the British Automation & Robot Association and Cranfield University to help companies consider and implement new automation strategies to reduce cost and increase competitiveness.

Rail investment increases

While new travel restrictions in this second wave of coronavirus will hit the rail sector, reducing passenger numbers and delaying recovery, it’s good news that investment in the industry is continuing. Network Rail has announced a landmark investment contract for 570 freight wagons to be built by Greenbrier Europe and leased from Swiss company Wascosa under a 10-year deal that includes maintenance from GB Railfreight.

Greenbrier’s European operation is headquartered in Poland, where we have a significant presence. We can support companies trading along the UK-Poland corridor with both finance and non-finance assistance, such as advice on overcoming bureaucracy and introductions to potential suppliers and buyers.

Meanwhile, the new UK-Japan trade deal, which is expected to increase trade between the two countries by £15.7bn a year, is positive for the UK’s automotive and rail manufacturing sectors. The deal will reduce tariffs on Japanese-made parts coming into the UK, streamline regulatory procedures and provide greater legal certainty on manufacturing operations for Japanese investors in the UK, such as Nissan and Hitachi.

Manufacturing sector news

The latest data from the Purchasing Managers Index for the manufacturing industry, released on 2 November, shows the index slipping from 54.1 to 53.7, suggesting a slower, but still positive rate of growth in the sector.

The data is in line with the recent CBI Industrial Trends Survey for the third quarter of 2020, which suggested manufacturing activity remains on a gradual path to a modest recovery. In the CBI survey, manufacturers reported that their output volumes were, on average, down 15% on more normal times because of the coronavirus crisis. They expect output to grow, although at a moderate rate, with new orders and recruitment remaining broadly flat.

More challenges lie ahead. Our recent Trade Barometer report suggested manufacturers see bureaucracy as their biggest challenge when trading in international markets and this anxiety persists as we prepare for the end of the post-Brexit transition period on 31 December. Manufacturers (like all businesses) need to take action now to be ready. Useful guidance is available from the Government and MakeUK. We can also provide support, including:

- detailed guidance on all the key areas of regulatory compliance businesses should consider as they prepare for transition

- detailed customs training in all key aspects of international trade

- guidance on what government support could be available for your business

- a company who can handle all of your customs documentation requirements, including completion of documents and submission onto the Customs Declaration Service (CDS) or Customs Handling of Import and Export Freight Service (CHIEF) platform.

Embracing digital

A new report from MakeUK and Sage reveals UK manufacturers took rapid and significant steps towards digitalisation when the pandemic struck, with nearly half adopting digital working practices within two weeks of lockdown. Some 94% of companies said staff were able to successfully work from home after just a fortnight of planning and installation. That’s impressive in industries often associated with manual tasks and a high proportion of production-based work.

The report found 9 in 10 manufacturers had benefited from adopting new digital technologies during the crisis, with 8 in 10 expecting to continue adopting new working practices. A quarter said these new technologies had increased productivity, with 12% pointing to increased production.

This acceleration will need to continue as manufacturing recovers. We can support investment in these key technologies, and we’re working with BDO (the accountancy and business advisory firm) to launch a new research and development tax credits funding product. This will help businesses to take advantage of the tax incentives available to firms that pursue innovation.

To discuss how we can help your business please contact: ccbsectorinsights@santander.co.uk